Base

Application

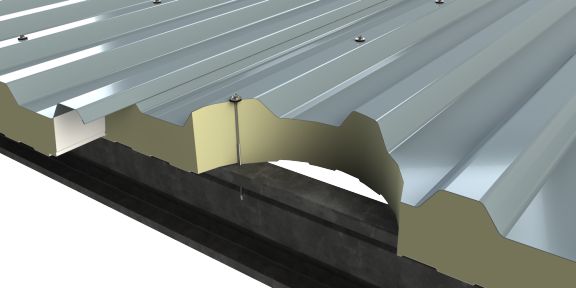

Sandwich panels

Bi-metal A2 304

Steel 17 Ga to 6 Ga

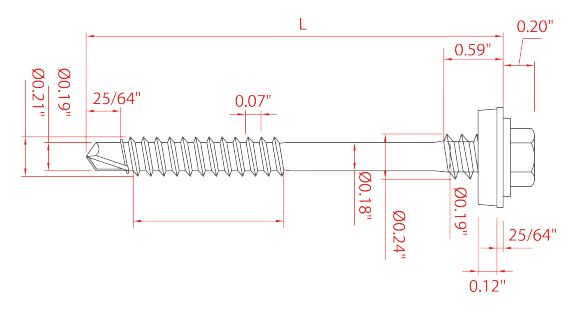

Specifications

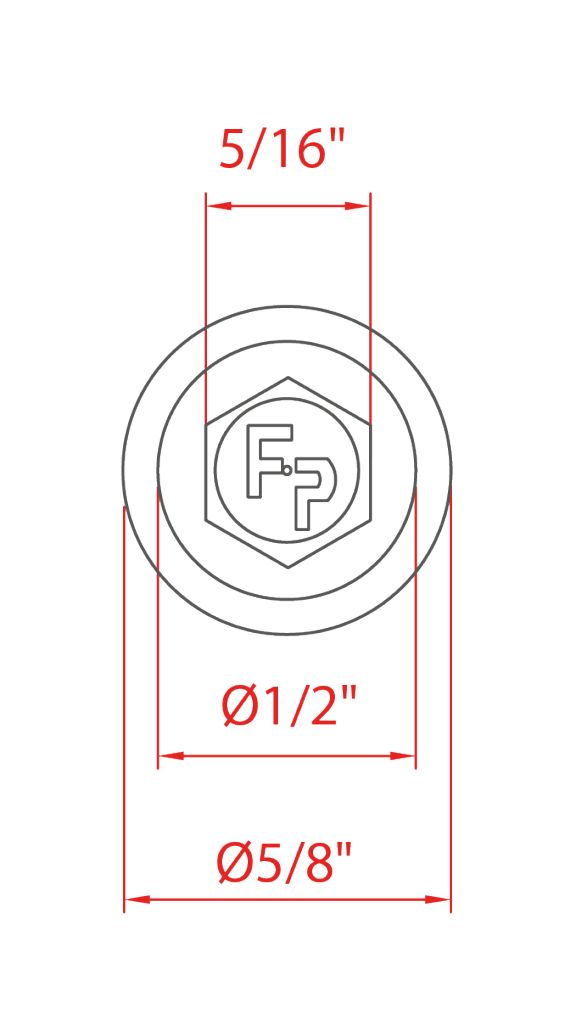

- Head style 5/16"

- Washer diameter standard 3/4”

- SS EPDM bond seal

- Support thread

- Thread for substructure steel 17 Ga to 6 Ga

- Drilling point 3

Options

- Powder coated in any desired RAL Color

- Washer diameter 5/8” or 27/32”

Certificates

Cross section

Applications

By using the below table, you can easily determine the required screw length.

| Size | Minimal Insulation thickness | Article code | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0 ” | 25/32” | 1 18/32” | 2 11/32” | 3 4/32” | 3 29/32” | 4 22/32” | 5 15/32” | 6 8/32” | 7 1/32” | 7 26/32” | 8 19/32” | 9 12/32” | 10 5/32” | ||

| #12 - #14 x 2 1/8" | 0 - 27/32”

|

1001035505519 | |||||||||||||

| #12 - #14 x 2 3/4" | 27/32” - 1 17/32”

|

1001035507219 | |||||||||||||

| #12 - #14 x 3 1/2" | 1 17/32” - 2 3/16”

|

1001035508919 | |||||||||||||

| #12 - #14 x 4 1/8" | 2 3/16” - 2 13/16”

|

1001035510519 | |||||||||||||

| #12 - #14 x 4 5/8” | 2 13/16” - 3 1/2”

|

1001035512219 | |||||||||||||

| #12 - #14 x 5 1/2" | 3 1/2” - 4 9/32”

|

1001035514219 | |||||||||||||

| #12 - #14 x 6 1/8" | 4 9/32” - 4 7/8”

|

1001035515719 | |||||||||||||

| #12 - #14 x 6 7/8" | 4 7/8” - 5 9/16”

|

1001035517519 | |||||||||||||

| #12 - #14 x 7 3/8" | 5 9/16” - 6 5/32”

|

1001035519019 | |||||||||||||

| #12 - #14 x 8 1/4" | 6 5/32” - 6 31/32”

|

1001035521019 | |||||||||||||

| #12 - #14 x 9" | 6 31/32” - 7 3/4”

|

1001035523019 | |||||||||||||

| #12 - #14 x 9 3/4" | 7 3/4” - 8 17/32”

|

1001035525019 | |||||||||||||

| #12 - #14 x 10 3/4" | 8 17/32” - 9 1/2”

|

1001035527519 | |||||||||||||

| #12 - #14 x 11 3/4" | 9 1/2” - 10 1/2”

|

1001035530019 | |||||||||||||

Order information

| Product | Size | Packaging | Article code |

|---|---|---|---|

| Sandwich Panel Screw #12 - #14 x 2 1/8" – BP3 | 2 1/8" | 100 pcs/box | 1001035505519 |

| Sandwich Panel Screw #12 - #14 x 2 3/4" – BP3 | 2 3/4" | 100 pcs/box | 1001035507219 |

| Sandwich Panel Screw #12 - #14 x 3 1/2" – BP3 | 3 1/2" | 100 pcs/box | 1001035508919 |

| Sandwich Panel Screw #12 - #14 x 4 1/8" – BP3 | 4 1/8" | 100 pcs/box | 1001035510519 |

| Sandwich Panel Screw #12 - #14 x 4 5/8” – BP3 | 4 5/8” | 100 pcs/box | 1001035512219 |

| Sandwich Panel Screw #12 - #14 x 5 1/2" – BP3 | 5 1/2" | 100 pcs/box | 1001035514219 |

| Sandwich Panel Screw #12 - #14 x 6 1/8" – BP3 | 6 1/8" | 100 pcs/box | 1001035515719 |

| Sandwich Panel Screw #12 - #14 x 6 7/8" – BP3 | 6 7/8" | 100 pcs/box | 1001035517519 |

| Sandwich Panel Screw #12 - #14 x 7 3/8" – BP3 | 7 3/8" | 100 pcs/box | 1001035519019 |

| Sandwich Panel Screw #12 - #14 x 8 1/4" – BP3 | 8 1/4" | 100 pcs/box | 1001035521019 |

| Sandwich Panel Screw #12 - #14 x 9" – BP3 | 9" | 100 pcs/box | 1001035523019 |

| Sandwich Panel Screw #12 - #14 x 9 3/4" – BP3 | 9 3/4" | 100 pcs/box | 1001035525019 |

| Sandwich Panel Screw #12 - #14 x 10 3/4" – BP3 | 10 3/4" | 100 pcs/box | 1001035527519 |

| Sandwich Panel Screw #12 - #14 x 11 3/4" – BP3 | 11 3/4" | 100 pcs/box | 1001035530019 |

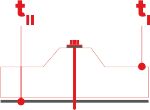

Mechanical properties

5/8''

3/4''

27/32''

| Materials | ||

|---|---|---|

| Screw | Stainless steel 1.4301 (A2) – according to EN ISO 3506 |

|

| Bond washer | Stainless steel 1.4301 (A2) – according to EN ISO 3506 | |

| Material A (tl) | SteelQuality S280GD, S320GD and S350GD - according to EN 10346 | |

| Material B (tll) | SteelQuality S235 – according to 10025-2 and S280GD, S320GD and S350GD - according to EN 10346 | |

| Drilling capacity | Steel ≤ 6 Ga | |

Washer diameter

5/8 "

| tN1 [Ga] | tII [inch] | |||||||||||||

| 22 Ga | 20 Ga | 17 Ga | 14 Ga | 11 Ga | 9 Ga | 4 Ga | ||||||||

|

VR,k [kN] | 28 Ga | 186 | 186 | 186 | 186 | 186 | 186 | 186 | |||||

| 26 Ga | 209 | 209 | 209 | 209 | 209 | 209 | 209 | |||||||

| 25 Ga | 249 | 249 | 249 | 249 | 249 | 249 | 249 | |||||||

| 23 Ga | 312 | 312 | 312 | 312 | 312 | 312 | 312 | |||||||

| 22 Ga | 409 | 429 | 429 | 429 | 429 | 429 | 429 | |||||||

| 21 Ga | 409 | 429 | 429 | 429 | 429 | 429 | 429 | |||||||

| 20 Ga | 409 | 429 | 429 | 429 | 429 | 429 | 429 | |||||||

|

NR,k [kN] | 28 Ga | 134 | 148 | 355 | 355 | 355 | 355 | 355 | |||||

| 26 Ga | 134 | 148 | 397 | 404 | 404 | 404 | 404 | |||||||

| 25 Ga | 134 | 148 | 397 | 474 | 474 | 474 | 474 | |||||||

| 23 Ga | 134 | 148 | 397 | 586 | 586 | 586 | 586 | |||||||

| 22 Ga | 134 | 148 | 397 | 645 | 755 | 755 | 755 | |||||||

| 21 Ga | 134 | 148 | 397 | 645 | 755 | 755 | 755 | |||||||

| 20 Ga | 134 | 148 | 397 | 645 | 755 | 755 | 755 | |||||||

|

u [mm] | 1 9/16" | 4 Ga | 6 Ga | 6 Ga | 9 Ga | 11 Ga | 14 Ga | 14 Ga | |||||

| 1 31/32" | 9/32" | 1/4" | 4 Ga | 6 Ga | 11 Ga | 11 Ga | 14 Ga | |||||||

| 2 11/32" | 11/32" | 5/16" | 9/32" | 4 Ga | 9 Ga | 11 Ga | 11 Ga | |||||||

| 3 1/8" | 15/32" | 13/32" | 3/8" | 5/16" | 4 Ga | 6 Ga | 9 Ga | |||||||

| 3 15/16" | 9/16" | 17/32" | 15/32" | 3/8" | 9/32" | 4 Ga | 6 Ga | |||||||

| 4 23/32" | 11/16" | 5/8" | 9/16" | 15/32" | 11/32" | 9/32" | 4 Ga | |||||||

| 5 1/2" | 13/16" | 3/4" | 11/16" | 17/32" | 13/32" | 5/16" | 1/4" | |||||||

| ≥6 9/32" | 15/16" | 27/32" | 25/32" | 5/8" | 15/32" | 3/8" | 5/16" | |||||||

- Above mentioned values are characteristic values

- To determine the design value, we suggest applying a material factor of γm = 1,33.

| Materials | ||

|---|---|---|

| Screw | Stainless steel 1.4301 (A2) – according to EN ISO 3506 |

|

| Bond washer | Stainless steel 1.4301 (A2) – according to EN ISO 3506 | |

| Material A (tl) | SteelQuality S280GD, S320GD and S350GD - according to EN 10346 | |

| Material B (tll) | SteelQuality S235 – according to 10025-2 and S280GD, S320GD and S350GD - according to EN 10346 | |

| Drilling capacity | Steel ≤ 6 Ga | |

Washer diameter

3/4 "

| tN1 [Ga] | tII [inch] | |||||||||||||

| 22 Ga | 20 Ga | 17 Ga | 14 Ga | 11 Ga | 9 Ga | 4 Ga | ||||||||

|

VR,k [kN] | 28 Ga | 186 | 186 | 186 | 186 | 186 | 186 | 186 | |||||

| 26 Ga | 209 | 209 | 209 | 209 | 209 | 209 | 209 | |||||||

| 25 Ga | 249 | 249 | 249 | 249 | 249 | 249 | 249 | |||||||

| 23 Ga | 312 | 312 | 312 | 312 | 312 | 312 | 312 | |||||||

| 22 Ga | 409 | 429 | 429 | 429 | 429 | 429 | 429 | |||||||

| 21 Ga | 409 | 429 | 429 | 429 | 429 | 429 | 429 | |||||||

| 20 Ga | 409 | 429 | 429 | 429 | 429 | 429 | 429 | |||||||

|

NR,k [kN] | 28 Ga | 134 | 148 | 397 | 481 | 481 | 481 | 481 | |||||

| 26 Ga | 134 | 148 | 397 | 517 | 517 | 517 | 517 | |||||||

| 25 Ga | 134 | 148 | 397 | 589 | 589 | 589 | 589 | |||||||

| 23 Ga | 134 | 148 | 397 | 645 | 705 | 705 | 705 | |||||||

| 22 Ga | 134 | 148 | 397 | 645 | 798 | 879 | 879 | |||||||

| 21 Ga | 134 | 148 | 397 | 645 | 798 | 879 | 879 | |||||||

| 20 Ga | 134 | 148 | 397 | 645 | 798 | 879 | 879 | |||||||

|

u [inch] | 1 9/16" | 4 Ga | 6 Ga | 6 Ga | 9 Ga | 11 Ga | 14 Ga | 14 Ga | |||||

| 1 31/32" | 9/32" | 1/4" | 4 Ga | 6 Ga | 11 Ga | 11 Ga | 14 Ga | |||||||

| 2 11/32" | 11/32" | 5/16" | 9/32" | 4 Ga | 9 Ga | 11 Ga | 11 Ga | |||||||

| 3 1/8" | 15/32" | 13/32" | 3/8" | 5/16" | 4 Ga | 6 Ga | 9 Ga | |||||||

| 3 15/16" | 9/16" | 17/32" | 15/32" | 3/8" | 9/32" | 4 Ga | 6 Ga | |||||||

| 4 23/32" | 11/16" | 5/8" | 9/16" | 15/32" | 11/32" | 9/32" | 4 Ga | |||||||

| 5 1/2" | 13/16" | 3/4" | 11/16" | 17/32" | 13/32" | 5/16" | 1/4" | |||||||

| ≥6 9/32" | 15/16" | 27/32" | 25/32" | 5/8" | 15/32" | 3/8" | 5/16" | |||||||

- Above mentioned values are characteristic values

- To determine the design value, we suggest applying a material factor of γm = 1,33.

| Materials | ||

|---|---|---|

| Screw | Stainless steel 1.4301 (A2) – according to EN ISO 3506 |

|

| Bond washer | Stainless steel 1.4301 (A2) – according to EN ISO 3506 | |

| Material A (tl) | SteelQuality S280GD, S320GD and S350GD - according to EN 10346 | |

| Material B (tll) | SteelQuality S235 – according to 10025-2 and S280GD, S320GD and S350GD - according to EN 10346 | |

| Drilling capacity | Steel ≤ 6 Ga | |

Washer diameter

27/32 "

| tN1 [Ga] | tII [inch] | |||||||||||||

| 22 Ga | 20 Ga | 17 Ga | 14 Ga | 11 Ga | 9 Ga | 4 Ga | ||||||||

|

VR,k [kN] | 28 Ga | 186 | 186 | 186 | 186 | 186 | 186 | 186 | |||||

| 26 Ga | 209 | 209 | 209 | 209 | 209 | 209 | 209 | |||||||

| 25 Ga | 249 | 249 | 249 | 249 | 249 | 249 | 249 | |||||||

| 23 Ga | 312 | 312 | 312 | 312 | 312 | 312 | 312 | |||||||

| 22 Ga | 409 | 429 | 429 | 429 | 429 | 429 | 429 | |||||||

| 21 Ga | 409 | 429 | 429 | 429 | 429 | 429 | 429 | |||||||

| 20 Ga | 409 | 429 | 429 | 429 | 429 | 429 | 429 | |||||||

|

NR,k [kN] | 28 Ga | 134 | 148 | 397 | 496 | 496 | 496 | 496 | |||||

| 26 Ga | 134 | 148 | 397 | 544 | 544 | 544 | 544 | |||||||

| 25 Ga | 134 | 148 | 397 | 629 | 629 | 629 | 629 | |||||||

| 23 Ga | 134 | 148 | 397 | 645 | 768 | 768 | 768 | |||||||

| 22 Ga | 134 | 148 | 397 | 645 | 798 | 948 | 975 | |||||||

| 21 Ga | 134 | 148 | 397 | 645 | 798 | 948 | 975 | |||||||

| 20 Ga | 134 | 148 | 397 | 645 | 798 | 948 | 975 | |||||||

|

u [inch] | 1 9/16" | 4 Ga | 6 Ga | 6 Ga | 9 Ga | 11 Ga | 14 Ga | 14 Ga | |||||

| 1 31/32" | 9/32" | 1/4" | 4 Ga | 6 Ga | 11 Ga | 11 Ga | 14 Ga | |||||||

| 2 11/32" | 11/32" | 5/16" | 9/32" | 4 Ga | 9 Ga | 11 Ga | 11 Ga | |||||||

| 3 1/8" | 15/32" | 13/32" | 3/8" | 5/16" | 4 Ga | 6 Ga | 9 Ga | |||||||

| 3 15/16" | 9/16" | 17/32" | 15/32" | 3/8" | 9/32" | 4 Ga | 6 Ga | |||||||

| 4 23/32" | 11/16" | 5/8" | 9/16" | 15/32" | 11/32" | 9/32" | 4 Ga | |||||||

| 5 1/2" | 13/16" | 3/4" | 11/16" | 17/32" | 13/32" | 5/16" | 1/4" | |||||||

| ≥6 9/32" | 15/16" | 27/32" | 25/32" | 5/8" | 15/32" | 3/8" | 5/16" | |||||||

- Above mentioned values are characteristic values

- To determine the design value, we suggest applying a material factor of γm = 1,33.

| Materials | ||

|---|---|---|

| Screw | Stainless steel 1.4301 (A2) – according to EN ISO 3506 |

|

| Bond washer | Stainless steel 1.4301 (A2) – according to EN ISO 3506 | |

| Material A (tl) | SteelQuality S280GD, S320GD and S350GD - according to EN 10346 | |

| Material B (tll) | SteelQuality S235 – according to 10025-2 and S280GD, S320GD and S350GD - according to EN 10346 | |

| Drilling capacity | Steel ≤ 6 Ga | |

"