Base

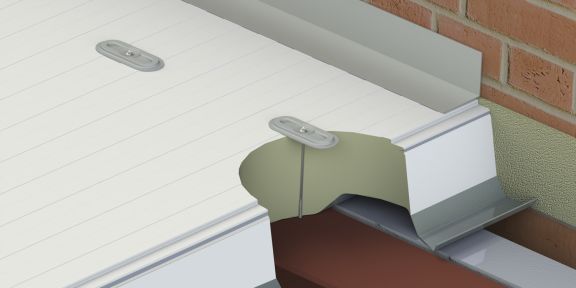

Application

Sandwich panels

Bi-metal A2 304

Steel 6 Ga to 25/32"

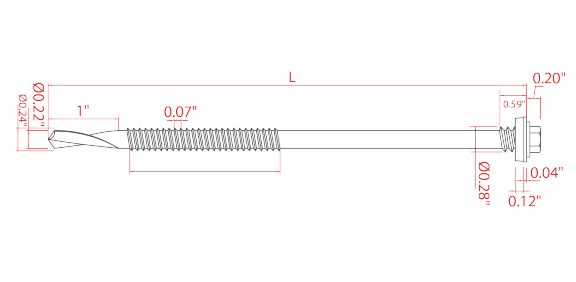

Specifications

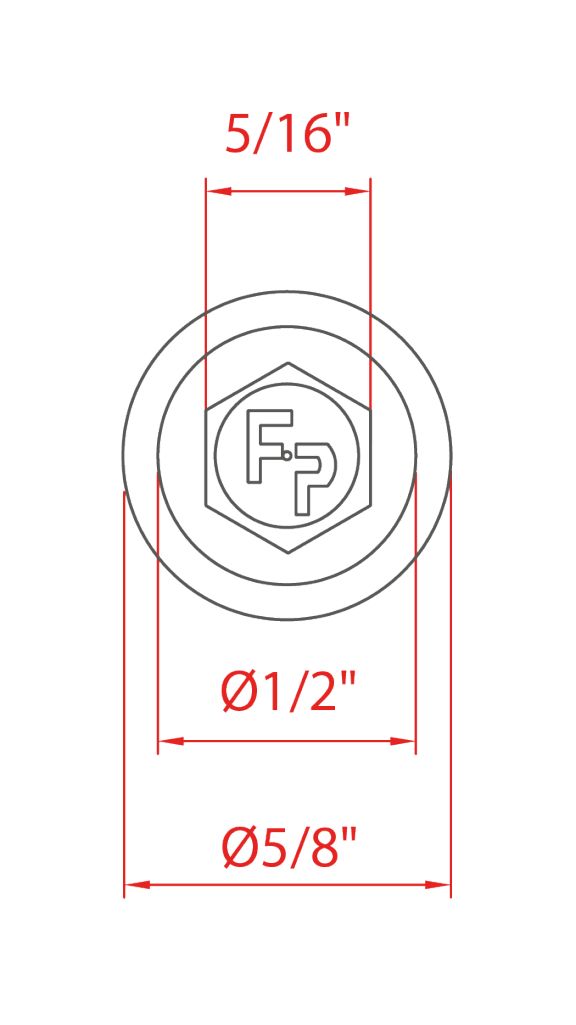

- Head style 5/16"

- Washer diameter standard 3/4”

- SS EPDM bond seal

- Support thread

- Thread for substructure steel 6 Ga to 25/32”

- Drilling point S20

Options

- Powder coated in any desired RAL Color

- Washer diameter 5/8” or 27/32”

Certificates

Cross section

Applications

By using the below table, you can easily determine the required screw length.

| Size | Minimal Insulation thickness | Article code | ||||||

|---|---|---|---|---|---|---|---|---|

| 0 ” | 25/32” | 1 18/32” | 2 11/32” | 3 4/32” | 3 29/32” | 4 22/32” | ||

| #12 - #14 x 6 5/8" | 3 17/32” - 4 23/32”

|

1001Q76317019 | ||||||

| #12 - #14 x 7 3/8" | 4 5/16” - 5 1/2”

|

1001Q76319019 | ||||||

| #12 - #14 x 9" | 5 29/32” - 7 1/16”

|

1001Q76323019 | ||||||

| #12 - #14 x 9 3/4" | 6 11/16” - 7 7/8”

|

1001Q76325019 | ||||||

| #12 - #14 x 10 5/8" | 7 15/32” - 8 21/32”

|

1001Q76327019 | ||||||

Order information

| Product | Afmeting | Verpakking | Artikelcode |

|---|---|---|---|

| Paneelbevestiger #12 - #14 x 6 5/8" – S20 | 6 5/8" | 100 st/doos | 1001Q76317019 |

| Paneelbevestiger #12 - #14 x 7 3/8" – S20 | 7 3/8" | 100 st/doos | 1001Q76319019 |

| Paneelbevestiger #12 - #14 x 9" – S20 | 9" | 100 st/doos | 1001Q76323019 |

| Paneelbevestiger #12 - #14 x 9 3/4" – S20 | 9 3/4" | 100 st/doos | 1001Q76325019 |

| Paneelbevestiger #12 - #14 x 10 5/8" – S20 | 10 5/8" | 100 st/doos | 1001Q76327019 |

Mechanical properties

5/8''

3/4''

27/32''

| Materials | ||

|---|---|---|

| Screw | RVS 1.4301 (A2) - according to EN3506 |

|

| Bond washer | RVS 1.4301 (A2) - according to EN3506 | |

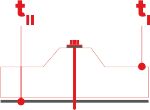

| Material A (tl) | S280GD, S320GD and S350GD according to EN 10346 | |

| Material B (tll) | S235 according to EN 10025-2, S280GD, S320GD and S350GD according to EN 10346 | |

| Drilling capacity | Steel ≤ 25/32” | |

Washer diameter

5/8 "

| tN1 [Ga] | tII [inch] | |||||||||||||||||

| 22 Ga | 21 Ga | 20 Ga | 19 Ga | 18 Ga | 17 Ga | 14 Ga | 11 Ga | 4 Ga | 3/8" | |||||||||

|

VR,k [kN] | 28 Ga | 256 | 256 | 256 | 256 | 256 | 256 | 256 | 256 | 256 | 256 | ||||||

| 26 Ga | 332 | 332 | 332 | 332 | 332 | 332 | 332 | 332 | 332 | 332 | ||||||||

| 25 Ga | 391 | 391 | 391 | 391 | 391 | 391 | 391 | 391 | 391 | 391 | ||||||||

| 23 Ga | 485 | 485 | 485 | 485 | 485 | 485 | 485 | 485 | 485 | 485 | ||||||||

| 22 Ga | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | ||||||||

| 21 Ga | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | ||||||||

| 20 Ga | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | ||||||||

| 19 Ga | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | ||||||||

| 18 Ga | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | ||||||||

|

NR,k [kN] | 28 Ga | 132 | 177 | 218 | 263 | 303 | 357 | 357 | 357 | 357 | 357 | ||||||

| 26 Ga | 132 | 177 | 218 | 263 | 303 | 377 | 377 | 377 | 377 | 377 | ||||||||

| 25 Ga | 132 | 177 | 218 | 263 | 303 | 388 | 406 | 406 | 406 | 406 | ||||||||

| 23 Ga | 132 | 177 | 218 | 263 | 303 | 388 | 454 | 454 | 454 | 454 | ||||||||

| 22 Ga | 132 | 177 | 218 | 263 | 303 | 388 | 526 | 526 | 526 | 526 | ||||||||

| 21 Ga | 132 | 177 | 218 | 263 | 303 | 388 | 557 | 586 | 586 | 586 | ||||||||

| 20 Ga | 132 | 177 | 218 | 263 | 303 | 388 | 557 | 586 | 586 | 586 | ||||||||

| 19 Ga | 132 | 177 | 218 | 263 | 303 | 388 | 557 | 586 | 586 | 586 | ||||||||

| 18 Ga | 132 | 177 | 218 | 263 | 303 | 388 | 557 | 586 | 586 | 586 | ||||||||

|

u [inch] | 1 9/16" | 3/8" | 6 Ga | 6 Ga | 6 Ga | 6 Ga | 6 Ga | 6 Ga | 6 Ga | 11 Ga | 11 Ga | ||||||

| 1 31/32" | 15/32" | 4 Ga | 4 Ga | 4 Ga | 4 Ga | 4 Ga | 4 Ga | 4 Ga | 11 Ga | 11 Ga | ||||||||

| 2 11/32" | 9/16" | 9/32" | 9/32" | 9/32" | 9/32" | 9/32" | 9/32" | 9/32" | 9 Ga | 9 Ga | ||||||||

| 3 1/8" | 25/32" | 3/8" | 3/8" | 3/8" | 3/8" | 3/8" | 3/8" | 3/8" | 4 Ga | 4 Ga | ||||||||

| 3 15/16" | 31/32" | 15/32" | 15/32" | 15/32" | 15/32" | 15/32" | 15/32" | 15/32" | 9/32" | 9/32" | ||||||||

| 4 23/32" | 1 5/32" | 9/16" | 9/16" | 9/16" | 9/16" | 9/16" | 9/16" | 9/16" | 11/32" | 11/32" | ||||||||

| ≥6 9/32" | 1 9/16" | 25/32" | 25/32" | 25/32" | 25/32" | 25/32" | 25/32" | 25/32" | 15/32" | 15/32" | ||||||||

- Above mentioned values are characteristic values

- To determine the design value, we suggest applying a material factor of γm = 1,33.

| Materials | ||

|---|---|---|

| Screw | RVS 1.4301 (A2) - according to EN3506 |

|

| Bond washer | RVS 1.4301 (A2) - according to EN3506 | |

| Material A (tl) | S280GD, S320GD and S350GD according to EN 10346 | |

| Material B (tll) | S235 according to EN 10025-2, S280GD, S320GD and S350GD according to EN 10346 | |

| Drilling capacity | Steel ≤ 25/32” | |

Washer diameter

3/4 "

| tN1 [Ga] | tII [inch] | |||||||||||||||||

| 22 Ga | 21 Ga | 20 Ga | 19 Ga | 18 Ga | 17 Ga | 14 Ga | 11 Ga | 4 Ga | 3/8" | |||||||||

|

VR,k [kN] | 28 Ga | 256 | 256 | 256 | 256 | 256 | 256 | 256 | 256 | 256 | 256 | ||||||

| 26 Ga | 332 | 332 | 332 | 332 | 332 | 332 | 332 | 332 | 332 | 332 | ||||||||

| 25 Ga | 391 | 391 | 391 | 391 | 391 | 391 | 391 | 391 | 391 | 391 | ||||||||

| 23 Ga | 485 | 485 | 485 | 485 | 485 | 485 | 485 | 485 | 485 | 485 | ||||||||

| 22 Ga | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | ||||||||

| 21 Ga | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | ||||||||

| 20 Ga | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | ||||||||

| 19 Ga | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | ||||||||

| 18 Ga | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | ||||||||

|

NR,k [kN] | 28 Ga | 132 | 177 | 218 | 263 | 303 | 388 | 422 | 422 | 422 | 422 | ||||||

| 26 Ga | 132 | 177 | 218 | 263 | 303 | 388 | 508 | 508 | 508 | 508 | ||||||||

| 25 Ga | 132 | 177 | 218 | 263 | 303 | 388 | 557 | 557 | 557 | 557 | ||||||||

| 23 Ga | 132 | 177 | 218 | 263 | 303 | 388 | 557 | 636 | 636 | 636 | ||||||||

| 22 Ga | 132 | 177 | 218 | 263 | 303 | 388 | 557 | 753 | 753 | 753 | ||||||||

| 21 Ga | 132 | 177 | 218 | 263 | 303 | 388 | 557 | 849 | 874 | 874 | ||||||||

| 20 Ga | 132 | 177 | 218 | 263 | 303 | 388 | 557 | 849 | 874 | 874 | ||||||||

| 19 Ga | 132 | 177 | 218 | 263 | 303 | 388 | 557 | 849 | 874 | 874 | ||||||||

| 18 Ga | 132 | 177 | 218 | 263 | 303 | 388 | 557 | 849 | 874 | 874 | ||||||||

|

u [inch] | 1 9/16" | 3/8" | 6 Ga | 6 Ga | 6 Ga | 6 Ga | 6 Ga | 6 Ga | 6 Ga | 11 Ga | 11 Ga | ||||||

| 1 31/32" | 15/32" | 4 Ga | 4 Ga | 4 Ga | 4 Ga | 4 Ga | 4 Ga | 4 Ga | 11 Ga | 11 Ga | ||||||||

| 2 11/32" | 9/16" | 9/32" | 9/32" | 9/32" | 9/32" | 9/32" | 9/32" | 9/32" | 9 Ga | 9 Ga | ||||||||

| 3 1/8" | 25/32" | 3/8" | 3/8" | 3/8" | 3/8" | 3/8" | 3/8" | 3/8" | 4 Ga | 4 Ga | ||||||||

| 3 15/16" | 31/32" | 15/32" | 15/32" | 15/32" | 15/32" | 15/32" | 15/32" | 15/32" | 9/32" | 9/32" | ||||||||

| 4 23/32" | 1 5/32" | 9/16" | 9/16" | 9/16" | 9/16" | 9/16" | 9/16" | 9/16" | 11/32" | 11/32" | ||||||||

| ≥6 9/32" | 1 9/16" | 25/32" | 25/32" | 25/32" | 25/32" | 25/32" | 25/32" | 25/32" | 15/32" | 15/32" | ||||||||

- Above mentioned values are characteristic values

- To determine the design value, we suggest applying a material factor of γm = 1,33.

| Materials | ||

|---|---|---|

| Screw | RVS 1.4301 (A2) - according to EN3506 |

|

| Bond washer | RVS 1.4301 (A2) - according to EN3506 | |

| Material A (tl) | S280GD, S320GD and S350GD according to EN 10346 | |

| Material B (tll) | S235 according to EN 10025-2, S280GD, S320GD and S350GD according to EN 10346 | |

| Drilling capacity | Steel ≤ 25/32” | |

Washer diameter

27/32 "

| tN1 [Ga] | tII [inch] | |||||||||||||||||

| 22 Ga | 21 Ga | 20 Ga | 19 Ga | 18 Ga | 17 Ga | 14 Ga | 11 Ga | 4 Ga | 3/8" | |||||||||

|

VR,k [kN] | 28 Ga | 256 | 256 | 256 | 256 | 256 | 256 | 256 | 256 | 256 | 256 | ||||||

| 26 Ga | 332 | 332 | 332 | 332 | 332 | 332 | 332 | 332 | 332 | 332 | ||||||||

| 25 Ga | 391 | 391 | 391 | 391 | 391 | 391 | 391 | 391 | 391 | 391 | ||||||||

| 23 Ga | 485 | 485 | 485 | 485 | 485 | 485 | 485 | 485 | 485 | 485 | ||||||||

| 22 Ga | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | ||||||||

| 21 Ga | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | ||||||||

| 20 Ga | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | ||||||||

| 19 Ga | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | ||||||||

| 18 Ga | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | 627 | ||||||||

|

NR,k [kN] | 28 Ga | 132 | 177 | 218 | 263 | 303 | 388 | 440 | 440 | 440 | 440 | ||||||

| 26 Ga | 132 | 177 | 218 | 263 | 303 | 388 | 557 | 586 | 586 | 586 | ||||||||

| 25 Ga | 132 | 177 | 218 | 263 | 303 | 388 | 557 | 618 | 618 | 618 | ||||||||

| 23 Ga | 132 | 177 | 218 | 263 | 303 | 388 | 557 | 669 | 669 | 669 | ||||||||

| 22 Ga | 132 | 177 | 218 | 263 | 303 | 388 | 557 | 748 | 748 | 748 | ||||||||

| 21 Ga | 132 | 177 | 218 | 263 | 303 | 388 | 557 | 849 | 867 | 867 | ||||||||

| 20 Ga | 132 | 177 | 218 | 263 | 303 | 388 | 557 | 849 | 867 | 867 | ||||||||

| 19 Ga | 132 | 177 | 218 | 263 | 303 | 388 | 557 | 849 | 867 | 867 | ||||||||

| 18 Ga | 132 | 177 | 218 | 263 | 303 | 388 | 557 | 849 | 867 | 867 | ||||||||

|

u [inch] | 1 9/16" | 3/8" | 6 Ga | 6 Ga | 6 Ga | 6 Ga | 6 Ga | 6 Ga | 6 Ga | 11 Ga | 11 Ga | ||||||

| 1 31/32" | 15/32" | 4 Ga | 4 Ga | 4 Ga | 4 Ga | 4 Ga | 4 Ga | 4 Ga | 11 Ga | 11 Ga | ||||||||

| 2 11/32" | 9/16" | 9/32" | 9/32" | 9/32" | 9/32" | 9/32" | 9/32" | 9/32" | 9 Ga | 9 Ga | ||||||||

| 3 1/8" | 25/32" | 3/8" | 3/8" | 3/8" | 3/8" | 3/8" | 3/8" | 3/8" | 4 Ga | 4 Ga | ||||||||

| 3 15/16" | 31/32" | 15/32" | 15/32" | 15/32" | 15/32" | 15/32" | 15/32" | 15/32" | 9/32" | 9/32" | ||||||||

| 4 23/32" | 1 5/32" | 9/16" | 9/16" | 9/16" | 9/16" | 9/16" | 9/16" | 9/16" | 11/32" | 11/32" | ||||||||

| ≥6 9/32" | 1 9/16" | 25/32" | 25/32" | 25/32" | 25/32" | 25/32" | 25/32" | 25/32" | 15/32" | 15/32" | ||||||||

- Above mentioned values are characteristic values

- To determine the design value, we suggest applying a material factor of γm = 1,33.